Peking university develops next-gen microfluidic cooling for chips

As electronic devices continue to become smaller and more powerful, managing the heat they generate has become a critical challenge. High heat fluxesessentially, more heat concentrated in a smaller areacan raise device temperatures, potentially damaging sensitive components and causing malfunctions or even permanent failure. To prevent such issues, engineers rely on thermal management systems, including innovative cooling strategies. Among these, microfluidic cooling has emerged as a promising approach for efficiently dissipating heat from compact electronics.

Researchers at Peking University and the National Key Laboratory of Advanced Micro and Nano Manufacture Technology have recently introduced a new microfluidic cooling approach that could outperform many existing methods in both efficiency and effectiveness. Their findings, published in Nature Electronics , describe a three-layer microfluidic cooling device etched into a silicon substrate, capable of handling unprecedented heat fluxes.

"The miniaturization of advanced electronics can lead to high heat fluxes, which must be dissipated before they cause device degradation or failure," researchers Zhihu Wu, Wei Xiao, and colleagues wrote. "Embedded microfluidic cooling is of potential value in such systems, but devices are typically limited to heat fluxes below 2,000 W cm−2. We report a microfluidic cooling strategy that can dissipate heat fluxes up to 3,000 W cm−2 at a pumping power of only 0.9 W cm−2 using single-phase water as the coolant."

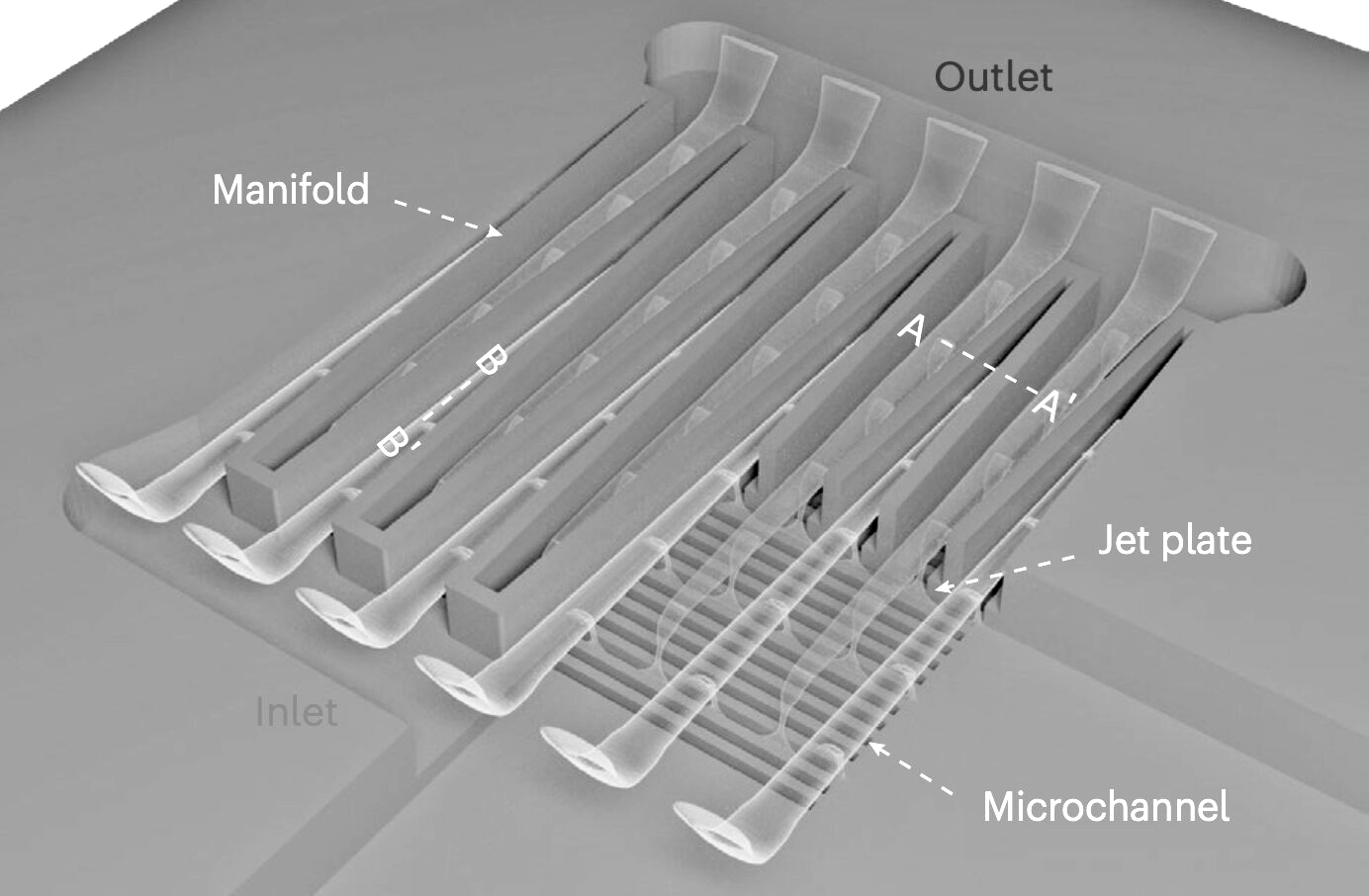

The three-layer device is structured as follows :

• Tapered Manifold Layer (Top Layer): Distributes water uniformly across the chip surface, ensuring all microchannels receive an equal amount of coolant. This uniform distribution prevents hotspots and promotes even cooling.

• Microjet Layer (Middle Layer): Features tiny nozzles that generate high-speed microjets, directing fluid streams precisely onto the chip’s surface. By targeting the thermal boundarythe region where heat accumulatesthis layer significantly improves heat transfer efficiency.

• Microchannel Layer (Bottom Layer): Contains microscopic grooves etched into the silicon that carry heated water away from the chip. The microchannels are designed with sawtooth-shaped sidewalls, which further enhance heat dissipation.

"Our approach is based on a three-tier structure that consists of a tapered manifold layer on the top, a microjet layer in the middle and a microchannel layer with sawtooth-shaped sidewalls at the bottom," Wu, Xiao, and their colleagues explained. "The structures are etched directly into the backside of the silicon substrate using standard microelectromechanical system technology. Moreover, the coefficient of performance can reach 13,000 and dissipate a heat flux of 1,000 W cm−2 at a maximum chip temperature rise of 65 K."

Initial testing of this device revealed that it removes heat more effectively than most previously introduced microfluidic cooling strategies, while requiring minimal pumping power0.9 W/cm². The design can also be fabricated on a large scale using existing manufacturing techniques, making it feasible for practical deployment in commercial electronics.

The researchers believe that this innovation could enable the development of smaller, more energy-efficient, and highly durable electronic devices. Beyond microchips, the team anticipates that future iterations of their microfluidic cooling technology could be evaluated across a broader range of electronics, potentially setting new standards for thermal management in miniaturized devices. "Our work demonstrates the potential for embedded microfluidic cooling in high-performance electronics," the team concluded. "This approach not only achieves high heat dissipation with low pumping power but also aligns with scalable manufacturing processes, paving the way for future electronic systems that are both compact and highly reliable."